HPLC troubleshooting can be tricky. Problems can arise at any time.

This guide will help you solve common issues. High-Performance Liquid Chromatography (HPLC) is essential in many labs. It separates and identifies compounds in a mixture. But what happens when things go wrong? Equipment issues, leaks, or poor results can disrupt your work.

Troubleshooting these problems can save time and frustration. This guide covers the most common HPLC issues and their solutions. You will find practical tips to keep your HPLC system running smoothly. Get ready to learn and fix your HPLC troubles with ease.

Introduction To Hplc Troubleshooting

Understanding HPLC troubleshooting is essential for maintaining accurate results. This guide provides practical solutions for common issues, helping you ensure reliable performance of your HPLC system.

High-performance liquid chromatography (HPLC) is vital in many labs. But, like any technology, it can face issues. Knowing how to troubleshoot is crucial. This guide helps you identify and solve common HPLC problems.

Importance Of Proper Maintenance

Proper maintenance extends the lifespan of your HPLC system. It ensures accurate results. Regular checks prevent major issues. Follow the manufacturer’s guidelines. Replace worn parts timely. Clean the system regularly. This avoids contamination. It saves time and money.

Common Hplc Problems

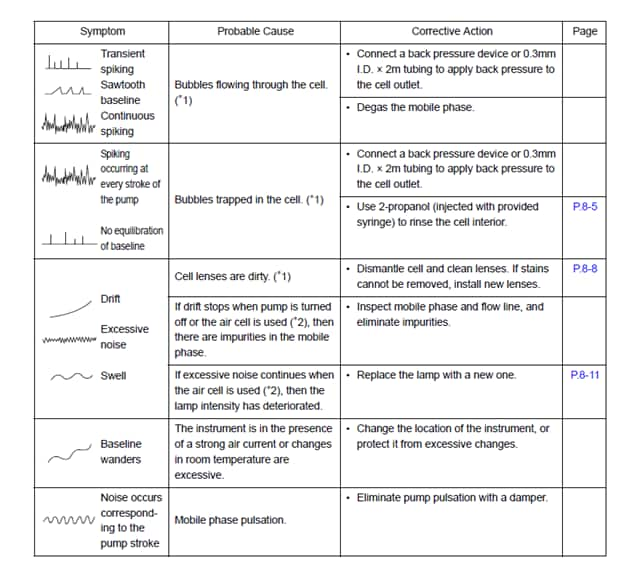

Several issues can occur with HPLC systems. These include leaks, pressure problems, and baseline noise. Each problem has specific causes and solutions.

Leaks are often due to loose fittings. Tighten connections to fix this. Pressure problems may arise from blockages. Check the column and tubing for clogs. Baseline noise can result from contaminated solvents. Use high-purity solvents to reduce noise.

In summary, HPLC troubleshooting is essential. Proper maintenance and understanding common problems can keep your system running smoothly.

Credit: www.ssi.shimadzu.com

Identifying Pressure Issues

Identifying pressure issues in HPLC systems is crucial for accurate results. Pressure problems can disrupt your analysis and damage your equipment. Understanding the causes and solutions of pressure issues helps maintain optimal performance.

High Pressure Causes

High pressure in HPLC systems usually signals blockages or restrictions. Common culprits include clogged filters or columns. Ensure you regularly check and clean these components. Another cause might be a buildup of particles in the system. Use high-quality solvents and filter your samples to reduce particle contamination. Additionally, improper tubing connections can lead to pressure spikes. Verify all connections are secure and free of leaks.

Low Pressure Solutions

Low pressure often indicates leaks or loose connections. Inspect all fittings and tighten them as needed. Damaged or worn seals can also cause pressure drops. Replace seals periodically to maintain system integrity. Another potential issue is a malfunctioning pump. Check the pump for any signs of wear or damage. If necessary, service or replace the pump to restore proper pressure levels.

Addressing Baseline Noise

Addressing baseline noise in High-Performance Liquid Chromatography (HPLC) is crucial for accurate results. Baseline noise can obscure peaks and reduce sensitivity. Understanding the causes and solutions can enhance your HPLC analysis.

Baseline Drift Factors

Baseline drift can result from various factors. Identifying and controlling these is essential:

- Temperature Fluctuations: Ensure the column and detector are temperature-controlled.

- Mobile Phase: Use high-purity solvents. Contaminants can cause drift.

- Column Equilibration: Allow the column to equilibrate properly before use.

- Sample Solvent: Match the sample solvent with the mobile phase.

Reducing Detector Noise

Detector noise can mask low-level signals. Here are some tips to reduce it:

- Detector Settings: Optimize settings for your specific analysis.

- Flow Rate: Ensure a consistent and appropriate flow rate.

- Column Maintenance: Regularly clean and maintain your column.

- Filters: Use in-line filters to remove particulates.

By addressing these factors, you can reduce baseline noise and improve your HPLC results.

Fixing Peak Shape Problems

In High-Performance Liquid Chromatography (HPLC), peak shape problems can affect data accuracy. Poor peak shapes can result from various issues. Let’s explore common problems and solutions.

Tailings And Broadening

Tailings and broadening of peaks are frequent issues in HPLC. Here are some common causes and solutions:

- Contaminated Column: Clean or replace the column regularly.

- Improper pH: Adjust the mobile phase pH to ensure proper separation.

- Column Overloading: Inject smaller sample volumes to avoid overloading.

- Incompatible Mobile Phase: Ensure the mobile phase is compatible with the stationary phase.

| Problem | Possible Cause | Solution |

|---|---|---|

| Tailings | Contaminated Column | Clean or replace the column |

| Broadening | Improper pH | Adjust pH of mobile phase |

Fronting Peaks

Fronting peaks appear when the front of the peak is sharper than the back. This can happen due to:

- Column Overloading: Inject smaller sample volumes.

- Improper Mobile Phase: Ensure the mobile phase is well prepared.

- Column Aging: Replace the column if it’s old or worn out.

By addressing these issues, you can improve peak shapes and achieve more accurate results. Regular maintenance and careful monitoring are key.

Dealing With Retention Time Variability

Retention time variability in HPLC can be frustrating. It affects the consistency and reliability of your results. Understanding the causes can help you troubleshoot effectively. This guide covers common issues and solutions. Let’s explore the key factors impacting retention time variability.

Column Issues

The column is a critical component in HPLC. Problems with the column can lead to retention time variability.

- Column Aging: Over time, columns can deteriorate. This can cause changes in retention times. Regularly check and replace old columns.

- Column Contamination: Contaminants can build up on the column. This affects the separation process. Clean or replace contaminated columns.

- Temperature Fluctuations: Temperature changes can impact the column performance. Use a column oven to maintain a stable temperature.

Mobile Phase Concerns

The mobile phase plays a vital role in HPLC. Issues with the mobile phase can cause retention time variability.

- Inconsistent Composition: Ensure the mobile phase composition is consistent. Variations can lead to different retention times. Use precise measurements when preparing the mobile phase.

- pH Changes: pH levels can affect retention times. Monitor and adjust the pH of the mobile phase as needed.

- Solvent Purity: Impurities in solvents can cause problems. Use high-purity solvents to avoid contamination.

By addressing these column and mobile phase issues, you can reduce retention time variability. This ensures more reliable and consistent HPLC results.

Credit: ymc.eu

Handling Ghost Peaks

Ghost peaks in High-Performance Liquid Chromatography (HPLC) can be frustrating. These unexpected signals can cause confusion and affect your results. Let’s explore how to handle ghost peaks effectively.

Contamination Sources

Ghost peaks often originate from contamination. Regular cleaning of your equipment is crucial. Pay attention to the following contamination sources:

- Solvents: Use high-purity solvents. Contaminated solvents can introduce ghost peaks.

- Glassware: Clean all glassware thoroughly. Residues can cause contamination.

- Mobile Phase: Always filter your mobile phase. Particulates can lead to ghost peaks.

- Sample Vials: Use clean vials. Contaminants in vials can also contribute to ghost peaks.

Improving Sample Preparation

Proper sample preparation is key to avoiding ghost peaks. Follow these tips to improve sample preparation:

- Filtration: Filter your samples before injection. This removes particulates that could cause ghost peaks.

- Degassing: Degas your samples and solvents. Air bubbles can lead to inconsistent results.

- Consistent Techniques: Use consistent techniques for sample handling. Variations can lead to contamination.

- Use Clean Equipment: Ensure all equipment is clean. Residues from previous samples can contaminate new ones.

By addressing contamination sources and improving sample preparation, you can significantly reduce ghost peaks. This will lead to more accurate and reliable HPLC results.

Solving Injection Problems

Solving injection problems is crucial for maintaining the accuracy of HPLC results. Injection issues can lead to poor reproducibility, affecting the overall quality of the analysis. Addressing these problems can enhance the reliability of your HPLC system.

Leakage Issues

Leakage during injection can cause significant data discrepancies. First, inspect all fittings and connections for tightness. Loose connections often lead to leaks. Next, check the injector seal. A worn-out seal can cause leaks, affecting sample integrity. Replace it if necessary.

Examine the syringe for damage. Cracked syringes can also leak. Regular maintenance of the injector is key. Clean the injector components frequently. This prevents residue buildup, reducing the risk of leaks.

Injection Volume Consistency

Consistent injection volume is vital for accurate results. Inconsistent volumes can skew data. First, calibrate the injector regularly. This ensures the volume injected is accurate. Next, inspect the sample loop. A damaged loop can lead to volume inconsistencies.

Check for air bubbles in the syringe. Air bubbles can cause incorrect volume measurements. Use a degasser to remove them. Ensure the sample is properly mixed. Inconsistent mixing can lead to inaccurate injection volumes.

Regular maintenance and proper calibration of the injection system are essential. This ensures consistent and accurate injection volumes, leading to reliable HPLC results.

Optimizing Column Performance

Optimizing Column Performance in High-Performance Liquid Chromatography (HPLC) is vital for accurate results. Proper column care ensures consistent, reliable data. Follow these tips to enhance column longevity and performance.

Column Storage Tips

Correct storage of HPLC columns extends their lifespan. Always store columns in an appropriate solvent. Avoid using water for long-term storage. Water can cause microbial growth. Use a mixture of organic solvent and water instead. For reversed-phase columns, store in 100% acetonitrile. Keep end plugs in place to avoid drying out.

| Column Type | Storage Solvent |

|---|---|

| Reversed-Phase | 100% Acetonitrile |

| Normal-Phase | Hexane or Isopropanol |

| Ion-Exchange | Water with 20% Methanol |

Regeneration Techniques

Over time, columns may degrade or become contaminated. Regeneration helps restore performance. Follow these steps to regenerate your column:

- Flush with a strong solvent. This removes contaminants.

- Use a gradient wash. Start with water, then increase organic solvent.

- Run a low-pH buffer. This can help remove ionic impurities.

- Rinse with water and then with your storage solvent.

Always consult the manufacturer’s guidelines before regeneration. Using the wrong solvent can damage your column.

Maintaining The Hplc System

Maintaining the HPLC system is vital for consistent, reliable results. Proper care ensures the system runs smoothly and extends its lifespan. Regular maintenance helps prevent unexpected breakdowns and costly repairs. Let’s explore essential practices under the following subheadings.

Routine System Checks

Routine system checks are crucial for maintaining HPLC performance. Inspect the system daily for any leaks or unusual noises. Check the pressure readings and ensure they are within the normal range. Verify that all connections are secure and no fittings are loose.

Regularly monitor the baseline noise and drift. Significant changes may indicate problems. Clean the injection port and replace the septum as needed. Ensure the mobile phase solvents are fresh and properly degassed. These checks help identify issues early and maintain system reliability.

Preventative Maintenance Strategies

Preventative maintenance strategies help keep the HPLC system in optimal condition. Schedule regular service visits with a qualified technician. They can perform in-depth inspections and address potential problems. Replace worn or damaged parts before they fail.

Implement a regular cleaning schedule for the system. Clean the autosampler, column, and detector to prevent contamination. Use appropriate solvents to flush the system and remove any residues. Store the system properly when not in use to avoid damage.

Keep detailed maintenance records. Note any issues, repairs, and parts replacements. This helps track the system’s health and plan future maintenance. Proper care and attention can significantly extend the life of your HPLC system.

Credit: www.researchgate.net

Frequently Asked Questions

What Causes High Backpressure In Hplc?

High backpressure is often caused by blockages. Check for clogs in the column, injector, or tubing.

Why Is My Hplc Baseline Noisy?

A noisy baseline can be due to air bubbles, dirty mobile phase, or detector issues. Ensure all parts are clean.

How Do I Fix Peak Tailing In Hplc?

Peak tailing usually occurs due to column contamination. Clean or replace the column to solve the issue.

What Should I Do If My Hplc Peaks Are Missing?

Missing peaks can happen due to injector problems or incorrect mobile phase. Verify system settings and components.

Why Are My Hplc Peaks Broad?

Broad peaks are often a result of slow flow rates or column issues. Check the flow rate and column condition.

Conclusion

A successful HPLC run starts with proper troubleshooting. Identify the problem first. Check the system’s components. Inspect the mobile phase. Clean or replace the column. Ensure all connections are secure. Regular maintenance prevents many issues. Follow these simple steps to keep your HPLC system running smoothly.

Happy troubleshooting!