Experiencing issues with your Baxter Peritoneal Dialysis machine can be frustrating. Effective troubleshooting can save you time and stress.

Dialysis is a life-saving treatment, and the Baxter Peritoneal Dialysis machine plays a crucial role for many. When problems arise, it is important to know how to address them quickly. Understanding the common issues and solutions can ensure your machine works smoothly.

In this guide, we will explore troubleshooting tips to help you manage your Baxter Peritoneal Dialysis machine efficiently. Whether you’re a patient or caregiver, these tips will help you keep the machine running properly. Let’s dive into the key steps for troubleshooting and ensure your dialysis process remains uninterrupted.

Introduction To Baxter Peritoneal Dialysis Machine

The Baxter Peritoneal Dialysis Machine is a vital tool for home dialysis. It helps patients with kidney failure filter waste from their blood. Proper usage ensures effective treatment and better health outcomes.

Importance Of Proper Functioning

Proper functioning of the Baxter Peritoneal Dialysis Machine is crucial. It ensures the dialysis process runs smoothly. A malfunction can lead to incomplete dialysis, causing health issues. Regular maintenance and troubleshooting keep the machine in top condition. This reduces the risk of complications and enhances patient safety.

Common Issues Faced

Users often face issues with the Baxter Peritoneal Dialysis Machine. Here are some common problems:

- Low drain volume

- Blocked catheter

- Power failures

- Alarm errors

Understanding these issues helps in quick troubleshooting. Let’s look into these problems in detail:

| Issue | Possible Cause | Solution |

|---|---|---|

| Low drain volume | Catheter blockage | Check for kinks or blockages |

| Blocked catheter | Improper positioning | Reposition the patient |

| Power failures | Loose connections | Ensure all plugs are secure |

| Alarm errors | Various reasons | Refer to the manual |

Regular checks and maintenance minimize these issues. Always refer to the user manual for specific troubleshooting steps.

Credit: www.bioclinicalservices.com.au

Setting Up The Machine

Setting up the Baxter Peritoneal Dialysis Machine correctly is crucial. It ensures smooth operation and effective treatment. Follow these steps for a seamless setup.

Correct Equipment Placement

Place the machine on a sturdy surface. Ensure it is level. Keep the machine away from direct sunlight. Avoid placing it near heat sources. Position it near a power outlet. Ensure easy access to the machine.

Initial Checks

Check the power cord for any damage. Ensure it is properly connected. Verify that the power switch is off. Inspect the machine for any visible defects. Ensure all components are present. Confirm you have the correct supplies.

Check the dialysate solution bags. Ensure they are not expired. Verify the correct type and volume. Inspect the tubing for any kinks or damage. Ensure the connectors are clean and undamaged. Prepare the machine for use by following the user manual.

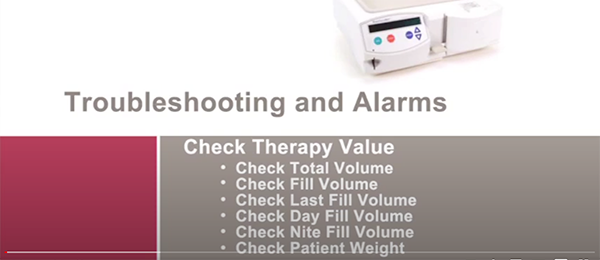

Addressing Alarms

Alarms on the Baxter Peritoneal Dialysis Machine can be stressful. But they help keep the treatment safe and effective. Understanding and resolving these alarms is crucial. Let’s explore how to address these alarms efficiently.

Understanding Alarm Types

The Baxter Peritoneal Dialysis Machine has various alarm types. Each alarm indicates a specific issue. Common alarm types include:

- Low Flow Alarm: Indicates restricted fluid flow.

- High Pressure Alarm: Suggests blocked tubing or catheter.

- Temperature Alarm: Signals fluid temperature out of range.

- Leak Alarm: Detects fluid leakage.

Each alarm has a unique sound and display message. Understanding these can help you identify and resolve issues quickly.

Steps To Resolve Alarms

Follow these steps to resolve alarms:

- Identify the Alarm: Check the display for the alarm message.

- Pause the Machine: Press the pause button to stop the operation.

- Check Connections: Ensure all connections are secure.

- Inspect Tubing: Look for kinks, blockages, or leaks in the tubing.

- Restart the Machine: After addressing the issue, restart the machine.

For persistent alarms, consult the user manual or contact technical support. Regular maintenance and proper setup can prevent many alarms.

Addressing alarms promptly ensures the dialysis process continues smoothly. Always stay vigilant and proactive in troubleshooting.

Fluid Flow Problems

Fluid flow problems in Baxter peritoneal dialysis machines can disrupt treatments. These issues affect the effectiveness of the dialysis process. Understanding the causes and solutions can help maintain proper machine function.

Causes Of Flow Issues

Several factors can cause fluid flow problems in dialysis machines. Blockages in the tubing or filters are common. Kinks in the tubes can also obstruct fluid flow. Air bubbles in the system might create pressure changes. Clogged filters from sediment or debris reduce fluid movement. Incorrect machine settings may also disrupt flow.

Solutions For Blockages

Addressing blockages involves several steps. First, check the tubing for kinks and straighten them out. Examine the filters for any debris or sediment. Clean or replace the filters if needed. Ensure all connections are secure and tight. Remove any air bubbles by priming the system. Verify that the machine settings are correct and properly configured.

Dealing With Leaks

Dealing with leaks in the Baxter Peritoneal Dialysis Machine can be stressful. Leaks can disrupt treatment and cause anxiety. Proper troubleshooting ensures smooth operation and peace of mind. This section covers how to identify and fix leaks in the machine.

Identifying Leak Sources

First, identify where the leak is coming from. Check these common areas:

- Connection points: Inspect tubing connections.

- Drain bag: Look for tears or punctures.

- Fluid bags: Check for leaks at seals.

- Machine exterior: Examine the outer body for damage.

Use a flashlight to see better. Sometimes, leaks are small and hard to spot. A careful inspection helps find the source quickly.

Fixing Leaks Effectively

Once the source is identified, follow these steps to fix the leak:

- Tighten connections: Ensure all tubes and connectors are secure.

- Replace damaged parts: If a bag or tube is damaged, replace it. Ensure you use Baxter-approved parts.

- Seal minor leaks: Use medical tape to seal small leaks temporarily.

- Check for blockages: A blockage can cause pressure buildup, leading to leaks. Clear any blockages you find.

After fixing the leak, monitor the machine. Ensure no further leaks occur. Regular maintenance can prevent many issues. Always follow the manufacturer’s guidelines.

Credit: renalcareus.baxter.com

Maintaining Sterility

Maintaining sterility while using the Baxter Peritoneal Dialysis Machine is crucial. Proper techniques ensure patient safety and optimal machine performance. This section provides detailed steps on maintaining sterility.

Sterile Techniques

Using sterile techniques is essential for peritoneal dialysis. Always wash your hands thoroughly before handling any equipment. Use a sterile field to place your supplies.

- Wear sterile gloves.

- Disinfect the work area.

- Use antiseptic solutions on the connection points.

These steps help prevent infection and ensure a successful dialysis session.

Preventing Contamination

Preventing contamination is vital for patient health. Follow these steps:

- Inspect all packaging for damage.

- Avoid touching sterile surfaces with non-sterile objects.

- Replace any suspect equipment immediately.

Use a table for quick reference:

| Step | Action |

|---|---|

| 1 | Check packaging |

| 2 | Avoid non-sterile contact |

| 3 | Replace suspect items |

Following these guidelines reduces the risk of contamination and promotes a safer dialysis process.

Electrical And Power Issues

Electrical and power issues can affect the performance of your Baxter Peritoneal Dialysis Machine. Power disruptions, faulty connections, or electrical failures may disrupt the machine’s operation. Addressing these issues promptly ensures smooth functioning and patient safety.

Power Supply Checks

Check the power cord for any visible damage. Sometimes, a simple cord replacement solves the issue. Ensure the power source is active and supplying adequate voltage. Use a multimeter to verify the voltage level. Confirm the power switch is turned on. If the machine does not power up, inspect the fuse.

Handling Electrical Failures

Electrical failures may require more in-depth troubleshooting. Check all internal connections for loose or corroded wires. Tighten any loose connections and clean corroded areas. Test the machine’s internal components with a multimeter. Look for any signs of short circuits or burnt components. If identified, replace the faulty parts immediately.

If the machine still fails, contact a professional technician. Sometimes, internal components might need expert handling. Ensure you follow safety procedures to avoid electrical hazards. Always unplug the machine before any internal inspection.

Regular Maintenance Tips

Regular maintenance is crucial for the Baxter Peritoneal Dialysis Machine. It ensures optimal performance and longevity. Following these tips can help prevent common issues and downtime.

Routine Cleaning

Routine cleaning is essential to keep the machine in good working order. Clean the exterior of the machine daily with a damp cloth. Use a mild detergent if needed. Make sure to avoid harsh chemicals that can damage the machine.

Focus on the touch screen and control panel. These areas are prone to dust and fingerprints. Clean them gently to avoid scratches.

Here is a simple cleaning schedule you can follow:

| Task | Frequency |

|---|---|

| Wipe exterior | Daily |

| Clean touch screen | Daily |

| Disinfect connectors | Weekly |

| Check for leaks | Weekly |

Scheduled Servicing

Scheduled servicing helps keep the machine running smoothly. Schedule professional servicing at least once a year. Technicians can identify and fix potential problems before they become serious.

During servicing, the technician will:

- Inspect all parts for wear and tear

- Replace any faulty components

- Update software if needed

- Test machine functionality

Regular servicing ensures the machine’s reliability. It also extends the machine’s lifespan.

When To Call For Professional Help

Peritoneal dialysis (PD) is a life-saving treatment for many patients with kidney failure. The Baxter Peritoneal Dialysis Machine is reliable, but like any machine, it can have issues. Knowing when to call for professional help is crucial for your health and safety.

Identifying Critical Problems

Some issues with the Baxter Peritoneal Dialysis Machine need immediate attention. If the machine displays error codes you cannot resolve, it’s a sign to seek help. Unusual noises or vibrations can also indicate serious problems. Leaks or spills during treatment are another red flag. Never ignore these signs. Your health depends on prompt action.

Contacting Technical Support

If you identify a critical problem, contact Baxter’s technical support. Keep your user manual and machine details handy. Describe the issue clearly. Follow their guidance carefully. They may ask you to perform simple checks or reset the machine. If the problem persists, they may send a technician to your home. Always prioritize your safety and well-being.

Credit: renalcareus.baxter.com

Frequently Asked Questions

How Do I Reset My Baxter Peritoneal Dialysis Machine?

To reset the machine, press the power button for 5 seconds. Follow on-screen instructions.

Why Is My Baxter Machine Beeping Continuously?

Continuous beeping often indicates an error. Check the display for error codes and consult the manual.

What Should I Do If The Machine Leaks?

If you notice a leak, stop the machine immediately. Check connections and tubing for damage or loose fittings.

How Can I Clear An Air Bubble Alarm?

Disconnect and reconnect the tubing. Ensure there are no visible bubbles. Restart the machine if needed.

What Does The “low Flow” Error Mean?

“Low Flow” suggests a blockage in the tubing. Check for kinks or obstructions and clear them. Restart the machine.

Conclusion

Troubleshooting your Baxter Peritoneal Dialysis Machine can seem challenging. Use the steps discussed to solve common issues quickly. Regular maintenance can prevent many problems. Always keep an eye on machine alerts. Remember, quick action can prevent bigger issues. If problems persist, contact a professional.

Your health and safety come first. Stay informed and proactive with your dialysis care.