To troubleshoot the Power Gear Leveling System, check fluid levels and inspect for hydraulic leaks. Ensure electrical connections are secure.

Power Gear Leveling Systems are essential for maintaining stability in RVs and motorhomes. Proper functioning is crucial for a smooth and safe travel experience. Common issues include hydraulic leaks, electrical connection problems, and low fluid levels. Addressing these problems promptly prevents further damage and costly repairs.

Regular maintenance and inspections help in early detection of potential issues. Understanding the basic troubleshooting steps can save time and provide peace of mind. This guide will help you identify and resolve common problems, ensuring your leveling system operates efficiently. Keep your RV or motorhome stable and safe by following these simple troubleshooting tips.

Introduction To Power Gear Leveling System

The Power Gear Leveling System is a crucial component in many RVs. It ensures that the vehicle remains level, providing stability and comfort. Understanding how it works and troubleshooting issues can save time and money.

What Is Power Gear?

Power Gear is a company specializing in leveling systems for RVs. They produce high-quality hydraulic and electric leveling systems. These systems help to keep your RV stable on uneven ground.

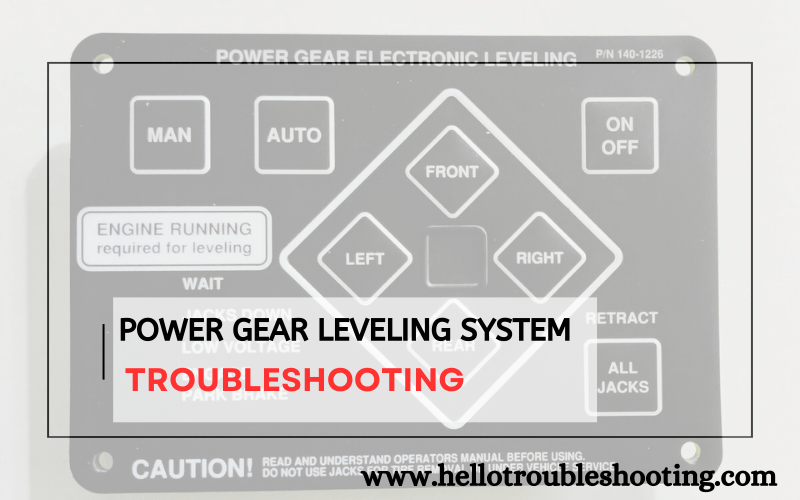

The components include jacks, a control panel, and hydraulic pumps. Each part works together to keep your RV level. Proper operation ensures a comfortable and safe camping experience.

Importance Of A Leveling System

A leveling system is vital for RV stability. It prevents the vehicle from rocking or tipping over. This stability is essential for safety and comfort.

Leveling systems also protect the RV’s structure. Uneven weight distribution can cause damage over time. A level RV ensures even weight distribution, reducing wear and tear.

Many RV appliances need a level surface to work correctly. For example, refrigerators and stoves function better when level. A leveling system ensures these appliances work efficiently.

A level RV also provides a better living experience. Walking, sleeping, and cooking are easier and more comfortable. The leveling system makes your RV feel like home, no matter where you park.

Common Issues Encountered

Having a Power Gear Leveling System can ease your RV experience. Yet, common issues may occur. Knowing them helps in quick troubleshooting. Here are the common problems and their solutions.

Hydraulic Leaks

Hydraulic leaks are among the most frequent problems. These leaks can cause the system to malfunction. They often result from damaged hoses or fittings.

- Inspect hoses regularly for any signs of wear or damage.

- Check fittings and connections for tightness.

- Replace any worn-out or damaged parts immediately.

It’s crucial to use the right type of hydraulic fluid. Incorrect fluids can damage the system. Always refer to the manual for the recommended fluid type.

Electrical Failures

Electrical failures are another common issue. These can stem from faulty wiring or blown fuses. Here are some steps to identify and fix electrical problems:

- Check the fuse box for any blown fuses.

- Inspect the wiring for any signs of damage or wear.

- Ensure all connections are secure and corrosion-free.

If the system still doesn’t work, the control panel might be faulty. Replacing the control panel can often solve the problem.

| Common Issues | Possible Causes | Solutions |

|---|---|---|

| Hydraulic Leaks | Damaged hoses or fittings | Inspect and replace as needed |

| Electrical Failures | Faulty wiring or blown fuses | Check fuses and wiring |

Regular maintenance can prevent many of these issues. Always follow the manufacturer’s guidelines for best results.

Pre-troubleshooting Checks

When dealing with the Power Gear Leveling System, it is crucial to perform pre-troubleshooting checks. These initial steps ensure that you do not miss simple issues that could be easily resolved. Proper checks can save time and effort.

Safety Precautions

Before starting any troubleshooting, always follow these safety precautions:

- Ensure the vehicle is parked on a flat surface.

- Switch off the engine and remove the key.

- Wear protective gloves and safety glasses.

- Keep children and pets away from the work area.

Safety first is essential to prevent accidents or injuries during troubleshooting.

Initial Visual Inspection

Begin with a thorough visual inspection:

- Check for any visible leaks in the hydraulic system.

- Inspect the leveling system for damaged or loose parts.

- Ensure all connectors and cables are securely attached.

Look for corroded wires or loose connections. These issues can cause the system to malfunction.

| Inspection Point | What to Look For |

|---|---|

| Hydraulic Fluid | Proper levels and no leaks |

| Connectors | Secure and corrosion-free |

| Leveling Jacks | No physical damage |

By following these pre-troubleshooting checks, you can identify and fix minor issues quickly. This step ensures that you do not overlook any simple problems before diving deeper into the system’s troubleshooting.

Hydraulic System Problems

The Power Gear Leveling System relies heavily on its hydraulic components. These components must function correctly to ensure proper leveling of your RV. Understanding common hydraulic system problems can save you time and stress.

Identifying Hydraulic Leaks

Hydraulic leaks are a frequent issue in leveling systems. Leaks can cause your RV to not level correctly. Here is how to identify them:

- Visual inspection: Look for fluid puddles under your RV.

- Check the hydraulic fluid level: Low levels can indicate a leak.

- Inspect hoses and connections: Look for wet or oily spots.

Finding a leak early can prevent further damage to your system.

Repairing Hydraulic Lines

Once you identify a leak, repairing the hydraulic lines is essential. Follow these steps to ensure a proper fix:

- Turn off the system: Ensure there is no pressure in the lines.

- Locate the damaged line: Trace the source of the leak.

- Remove the damaged section: Use a wrench to disconnect the line.

- Install a new line: Ensure it’s the same type and size.

- Tighten all connections: Secure the new line in place.

It’s crucial to check your work for any further leaks.

| Common Tools Needed | Usage |

|---|---|

| Wrench | To disconnect and connect hydraulic lines. |

| Hydraulic Fluid | To refill the system after repair. |

| Replacement Lines | To replace damaged sections. |

Always have these tools on hand for hydraulic repairs.

Electrical System Issues

The Power Gear Leveling System is crucial for RV stability. Electrical system issues can disrupt its functioning. Addressing these issues ensures smooth operation.

Checking Power Supply

First, verify the power supply to the system. Ensure the RV is connected to a reliable power source. Check the battery voltage using a multimeter. The voltage should be between 12.6 and 13.7 volts.

- If the voltage is low, charge the battery.

- Inspect the battery terminals for corrosion.

- Clean terminals with a baking soda solution if needed.

A faulty power supply can cause the system to malfunction. Addressing power issues is the first step in troubleshooting.

Inspecting Wiring Connections

Inspect the wiring connections for any signs of damage. Loose or corroded connections can interrupt the electrical flow. Check all the connectors and terminals.

- Tighten any loose connections.

- Replace damaged wires immediately.

- Use a wiring diagram to ensure correct connections.

Proper wiring connections are essential for the system’s performance. Regular inspections prevent unexpected failures.

| Issue | Solution |

|---|---|

| Low battery voltage | Charge the battery |

| Corroded terminals | Clean with baking soda solution |

| Loose connections | Tighten connections |

| Damaged wires | Replace wires |

Ensuring a proper electrical system is key to the Power Gear Leveling System’s success. Regular checks and maintenance can prevent many issues.

Sensor And Calibration Errors

The Power Gear Leveling System is crucial for RV stability. Sensor and calibration errors can disrupt its function. These errors affect the system’s ability to level properly. Regular checks and fixes can prevent these issues.

Testing Sensors

First, locate the sensors in your Power Gear Leveling System. Use a multimeter to test their functionality.

- Set the multimeter to the correct setting.

- Connect the multimeter probes to the sensor terminals.

- Read the values displayed on the multimeter.

Compare these values with the specifications in your system’s manual. If the readings are off, the sensor may be faulty.

Recalibrating The System

After testing the sensors, recalibrate the system if needed. Follow these steps:

- Turn off the leveling system.

- Ensure the RV is on a flat surface.

- Access the control panel of the system.

- Press the calibration button as per the manual.

- Wait for the system to complete the recalibration process.

Check the system’s performance after recalibration. Ensure it levels the RV correctly. Repeat the steps if necessary.

Maintenance Tips

Maintaining your Power Gear Leveling System ensures smooth operation. Regular checks and proper tools are key. Below are some essential maintenance tips to keep your system in top shape.

Regular Inspection Routine

Inspect your Power Gear Leveling System regularly. Early detection of issues prevents bigger problems. Follow this routine:

- Check for leaks: Ensure hydraulic fluid levels are adequate.

- Examine electrical connections: Look for loose or corroded wires.

- Inspect jacks: Ensure they extend and retract smoothly.

- Listen for unusual noises: Strange sounds may indicate problems.

Essential Maintenance Tools

Having the right tools makes maintenance easier. Here are some essentials:

| Tool | Purpose |

|---|---|

| Hydraulic fluid | Refill or top up system fluid levels |

| Multimeter | Test electrical connections and voltage |

| Wrench set | Tighten or loosen bolts and nuts |

| Cleaning cloths | Wipe down components and remove debris |

Always use high-quality tools. They ensure accurate maintenance and reduce the risk of damage.

When To Seek Professional Help

Troubleshooting your Power Gear Leveling System can be tricky. Some issues may be minor and easy to fix. Yet, others might need expert intervention. Knowing when to seek professional help is crucial. This guide helps you identify major problems and find a qualified technician.

Signs Of Major Problems

- Consistent Error Codes: If error codes keep showing up, it’s time to call an expert.

- Unusual Noises: Strange sounds during operation signal bigger issues.

- Fluid Leaks: Leaking hydraulic fluid is a serious concern. A professional should inspect it.

- System Unresponsive: If the system doesn’t respond, it’s a clear sign to seek help.

- Uneven Leveling: If your vehicle remains uneven, despite attempts to level it, you need expert help.

Choosing A Qualified Technician

Selecting the right technician ensures your system gets the best care. Consider the following factors:

- Certification: Ensure the technician has proper certifications for Power Gear systems.

- Experience: Check if they have experience specifically with Power Gear Leveling Systems.

- Reviews: Look for positive reviews and testimonials from previous clients.

- Warranty: Verify if the technician offers a warranty on their repairs.

- Service Range: Ensure they can handle a wide range of issues, not just basic repairs.

By recognizing major problems and choosing the right technician, you can ensure your Power Gear Leveling System remains in top condition. This proactive approach saves you time and prevents further damage.

Questions

How To Reset Power Gear Leveling System?

To reset, turn off the system, then power it back on. Check the manual for specific instructions.

Why Is My Power Gear System Not Leveling?

The system might not be leveling due to low hydraulic fluid, sensor issues, or electrical problems. Inspect these components.

What Does Blinking Light On Power Gear Mean?

A blinking light usually indicates an error. Refer to the manual for error code meanings and troubleshoot accordingly.

How To Check Hydraulic Fluid In Power Gear?

Locate the hydraulic reservoir, remove the cap, and check the fluid level. Refill if it’s below the recommended level.

Can Cold Weather Affect Power Gear System?

Yes, cold weather can thicken hydraulic fluid, causing the system to operate slowly. Warm up the system before use.

Conclusion

Troubleshooting your Power Gear Leveling System can be straightforward with the right steps. Regular maintenance ensures smooth operation. Always refer to the user manual for specific issues. Don’t hesitate to seek professional help if needed. Keeping your system in top shape guarantees a hassle-free experience on the road.