Check the power source and control switches for faults. Inspect hydraulic fluid levels and electrical connections.

Genie Boom Lifts are essential for various construction and maintenance tasks. Proper troubleshooting ensures their optimal performance and safety. Common issues include power failures, hydraulic problems, and electrical faults. Regularly check and maintain the power source, control switches, and hydraulic fluid levels.

Inspecting electrical connections can prevent unexpected downtimes. Keeping a maintenance log helps in identifying recurring issues. Training operators on basic troubleshooting can save time and reduce costs. Always refer to the user manual for specific troubleshooting steps. Ensuring routine inspections and addressing problems promptly extends the lifespan of the equipment. Efficient troubleshooting enhances productivity and safety on site.

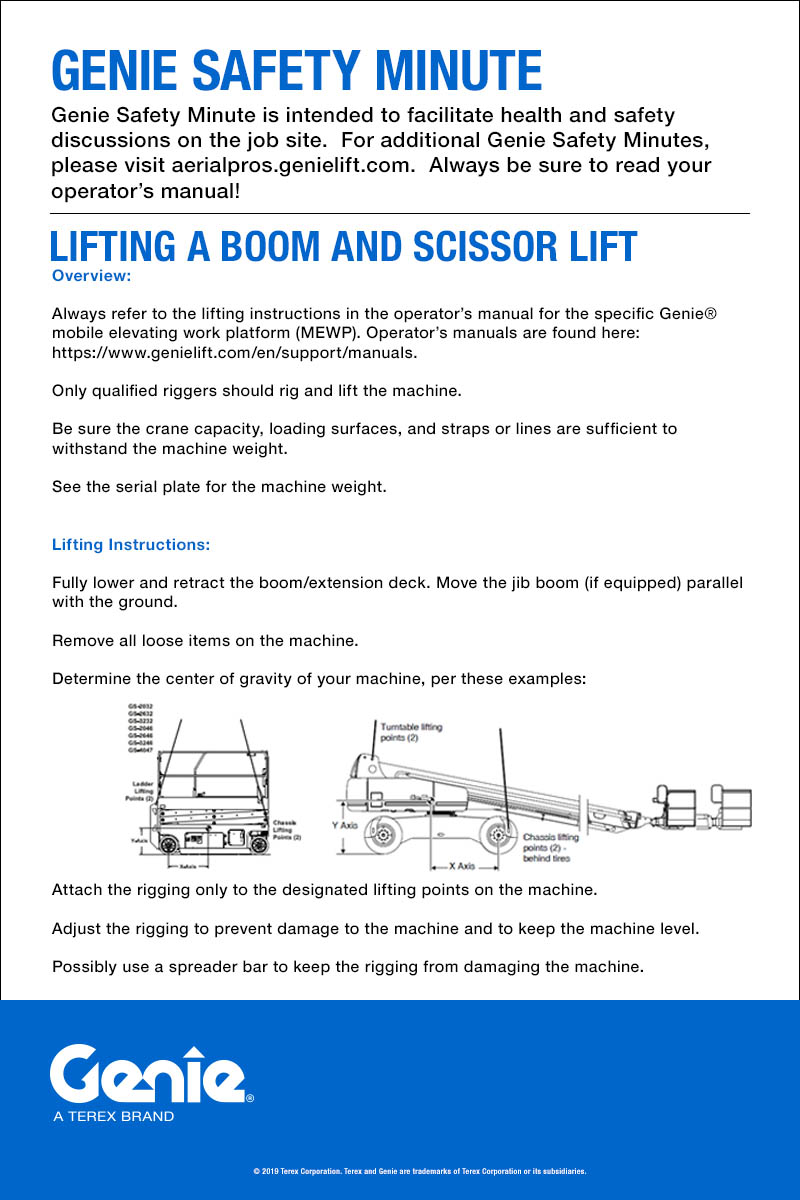

Credit: www.ebay.com.my

Common Issues

Genie Boom Lifts are reliable, but they sometimes face issues. Knowing these common problems helps you troubleshoot efficiently. Below, we discuss some frequent issues and their fixes.

Hydraulic Problems

Hydraulic systems can be tricky. Common hydraulic issues include:

- Hydraulic leaks: Check seals and hoses for wear.

- Low hydraulic fluid: Ensure fluid levels are adequate.

- Slow movement: This could indicate a blocked filter.

Regular maintenance can prevent most hydraulic problems. Always keep an eye on fluid levels and seals.

Electrical Failures

Electrical failures can halt your work. Common electrical issues are:

- Dead battery: Check battery charge and connections.

- Blown fuses: Inspect and replace any faulty fuses.

- Faulty wiring: Look for damaged or disconnected wires.

Use a multimeter to test electrical components. This ensures all parts are functioning.

Mechanical Malfunctions

Mechanical malfunctions often involve wear and tear. Common mechanical issues include:

- Worn-out gears: Inspect gears for signs of wear.

- Broken chains: Check for any broken or loose chains.

- Loose bolts: Ensure all bolts are tight and secure.

Regularly check and maintain mechanical parts. This extends the life of your Genie Boom Lift.

Safety Precautions

Working with a Genie Boom Lift requires strict safety measures. Proper safety precautions prevent accidents and ensure smooth operations. This section details essential safety steps to follow.

Personal Protective Equipment

Always wear the right Personal Protective Equipment (PPE) when using a Genie Boom Lift. PPE includes:

- Hard hats: Protects your head from falling objects.

- Safety glasses: Shields your eyes from debris.

- High-visibility vests: Makes you easily seen by others.

- Gloves: Protects your hands from sharp edges and chemicals.

- Steel-toe boots: Protects your feet from heavy items.

Always inspect your PPE before use. Ensure it is in good condition.

Lockout/tagout Procedures

Lockout/Tagout (LOTO) procedures are crucial for safety. They ensure the equipment is off and cannot start accidentally. Follow these steps:

- Turn off the boom lift and disconnect the power source.

- Apply a lock to the power switch to prevent it from turning on.

- Attach a tag that indicates the equipment is under maintenance.

- Ensure only authorized personnel can remove the lock and tag.

LOTO procedures protect workers from unexpected hazards. Always follow them strictly.

Diagnostic Tools

Troubleshooting a Genie Boom Lift requires precise diagnostic tools. These tools help identify and resolve issues quickly. Using the right tools ensures your equipment runs smoothly. Here, we will discuss some essential diagnostic tools.

Multimeters

A multimeter is crucial for diagnosing electrical issues. It measures voltage, current, and resistance. Use a multimeter to check battery health. It helps identify faulty wiring or connections. Always ensure your multimeter is calibrated.

- Measure voltage

- Check battery health

- Identify faulty wiring

Pressure Gauges

Pressure gauges are vital for checking hydraulic systems. They measure the pressure in hydraulic lines. Incorrect pressure can cause lift malfunctions. Regularly check pressure levels to ensure optimal performance.

| Task | Tool |

|---|---|

| Measure hydraulic pressure | Pressure gauge |

| Check system health | Pressure gauge |

Diagnostic Software

Diagnostic software is essential for modern Genie Boom Lifts. It helps identify complex issues. Connect the software to your lift’s control system. The software provides detailed error codes and solutions. Keep your software updated for accurate diagnostics.

- Connect to control system

- Identify error codes

- Find solutions

Hydraulic System Troubleshooting

Genie Boom Lifts are essential for various construction and maintenance tasks. Understanding hydraulic system troubleshooting ensures optimal performance and safety. This section covers key steps for diagnosing hydraulic issues.

Checking Fluid Levels

First, inspect the hydraulic fluid levels. Low fluid can cause system malfunction. Follow these steps:

- Locate the hydraulic fluid reservoir.

- Check the fluid level against the marked indicators.

- Ensure the fluid is at the recommended level.

- If low, add the correct hydraulic fluid type.

Always use the manufacturer’s recommended hydraulic fluid. Using the wrong type can damage the system.

Identifying Leaks

Leaks are common issues in hydraulic systems. Follow these steps to identify leaks:

- Visually inspect all hydraulic hoses and fittings.

- Look for wet spots or puddles under the lift.

- Check around the hydraulic cylinder seals.

- Use a clean cloth to wipe suspected areas.

If a leak is found, it must be repaired immediately. Delaying repairs can cause serious damage.

Testing Pressure

Testing the hydraulic pressure ensures the system operates within the correct parameters. Follow these steps:

- Attach a pressure gauge to the hydraulic system.

- Start the Genie Boom Lift and operate the controls.

- Read the pressure gauge and compare it with the manufacturer’s specifications.

- If pressure is too low or too high, adjustments may be needed.

Consult the manual for the correct pressure settings. Incorrect pressure can lead to system failures.

Electrical System Troubleshooting

When it comes to troubleshooting a Genie Boom Lift, the electrical system is crucial. Many common issues can be traced back to electrical faults. This section will guide you through the essential steps for electrical system troubleshooting.

Inspecting Wiring

Start by inspecting the wiring. Look for any visible damage. Check for loose connections or frayed wires.

- Look for any burnt marks on wires.

- Check for wires that are not tightly connected.

- Ensure all wires are in good condition.

Using a multimeter can help. Test the continuity of wires. This helps you find broken wires.

Battery Maintenance

Battery maintenance is key for the electrical system. Ensure the battery is fully charged.

- Check the battery terminals for corrosion.

- Clean the terminals if needed.

- Use a battery tester to check voltage levels.

A weak battery can cause many electrical issues. Replace old batteries if necessary.

Sensor Checks

Sensors play a critical role in the Genie Boom Lift. Faulty sensors can cause system errors.

- Inspect all sensors for visible damage.

- Ensure sensors are properly connected.

- Use diagnostic tools to test sensor functionality.

Replace any faulty sensors immediately. This ensures the lift operates smoothly.

Mechanical System Troubleshooting

Understanding the mechanical system of a Genie Boom Lift is key. Proper maintenance ensures safety and efficiency. This guide helps you troubleshoot common issues.

Lubrication Points

Regular lubrication keeps the boom lift running smoothly. Identify all lubrication points:

- Pivot points

- Boom sections

- Steering components

Use the manufacturer-recommended lubricant. Clean areas before applying new lubricant. Check lubrication intervals in the manual.

Component Wear

Inspect all components regularly. Look for signs of wear:

- Cracks

- Corrosion

- Deformation

Replace worn parts immediately. Use genuine Genie parts. Regular checks prevent bigger issues.

Alignment Issues

Alignment ensures the boom lift operates correctly. Misalignment affects stability and performance.

Steps to check alignment:

- Park the boom lift on a level surface.

- Check the base and boom alignment.

- Inspect the tires for even wear.

Correct any misalignment promptly. Follow the manual for alignment procedures. Proper alignment ensures safety.

Preventative Maintenance

Preventative maintenance is crucial for ensuring the longevity and efficiency of your Genie Boom Lift. Regular upkeep can prevent costly repairs and ensure the safety of operators. Below, we delve into essential maintenance practices that keep your equipment in top shape.

Scheduled Inspections

Regular inspections are vital for identifying potential issues before they become serious problems. Create a schedule for routine checks to ensure every part of the lift is functioning properly.

- Check hydraulic systems for leaks.

- Inspect the electrical systems and wiring.

- Examine tires and replace if worn out.

Document every inspection to track the lift’s condition over time. This helps in planning future maintenance activities more efficiently.

Cleaning Protocols

Keeping the Genie Boom Lift clean is not just about aesthetics. Dirt and debris can cause mechanical issues and reduce the lifespan of the machine.

- Wipe down control panels and seats regularly.

- Clean hydraulic components to prevent clogging.

- Wash the exterior to remove dirt and grime.

Use appropriate cleaning agents to avoid damage. Always follow the manufacturer’s guidelines for cleaning.

Parts Replacement

Replacing worn-out parts promptly is essential for the lift’s optimal performance. Keep an inventory of critical parts to minimize downtime.

| Part | Replacement Frequency |

|---|---|

| Hydraulic Hoses | Every 1,000 hours |

| Batteries | Every 500 hours |

| Tires | As needed |

Replace any damaged parts immediately to avoid further complications. Always use genuine parts for replacements to ensure compatibility and safety.

Credit: www.genielift.com

Expert Tips

Troubleshooting a Genie Boom Lift can save time and money. This guide provides expert tips for common issues. Follow these steps to keep your equipment running smoothly.

Common Pitfalls

Many operators face similar issues with Genie Boom Lifts. These common pitfalls can be avoided:

- Battery Problems: Ensure the battery is fully charged.

- Hydraulic Leaks: Check for any fluid leaks regularly.

- Electrical Issues: Inspect all wiring for damage.

- Engine Performance: Regularly maintain the engine.

Time-saving Tricks

Save time with these quick troubleshooting tricks:

- Regular Inspections: Conduct daily checks before use.

- Proper Lubrication: Keep all moving parts well-lubricated.

- Check Manuals: Always refer to the operator’s manual.

- Spare Parts: Keep essential spare parts on hand.

When To Call A Professional

Some problems need professional help. Call a technician if you face any of the following:

- Persistent Electrical Issues: Ongoing electrical problems need expert attention.

- Severe Hydraulic Leaks: Large fluid leaks require professional repair.

- Engine Failures: Engine not starting or performing poorly needs a specialist.

- Complex Diagnostics: Use experts for advanced troubleshooting tools.

Credit: www.ebay.com

Frequently Asked Questions

How To Fix Genie Boom Lift Hydraulic Issues?

Check hydraulic fluid levels and look for leaks. Inspect hoses and connections for damage or wear.

Why Is My Genie Boom Lift Not Starting?

Ensure the battery is charged and connections are secure. Check the ignition switch and starter motor.

What Causes Genie Boom Lift Engine Overheating?

Inspect the cooling system for blockages. Ensure the radiator is clean and the coolant level is adequate.

How To Troubleshoot Genie Boom Lift Electrical Problems?

Examine fuses and circuit breakers. Check wiring for any signs of wear or damage.

Why Is My Genie Boom Lift Not Lifting?

Verify the hydraulic system is functioning correctly. Inspect the lift cylinder and control valve for issues.

Conclusion

Efficient troubleshooting of Genie boom lifts ensures smooth operation and minimizes downtime. Regular maintenance checks are vital for longevity. Addressing issues promptly can save costs and enhance safety. Keep this guide handy for quick reference. A well-maintained lift boosts productivity and ensures reliability on the job site.