Is your Freightliner’s ABS not working and leaving you worried about safety and costly repairs? You’re not alone, and this issue needs your immediate attention.

Ignoring ABS problems can put you, your cargo, and others on the road at serious risk. But don’t panic—understanding why the ABS isn’t functioning and knowing when to seek professional service can save you time, money, and stress. Keep reading to find out what’s really going on with your Freightliner and how to get it back on track quickly and safely.

Credit: www.reddit.com

Common Causes Of Abs Failure

The ABS system in Freightliner trucks helps keep the wheels from locking during braking. When this system fails, it can affect vehicle safety and control. Understanding common causes of ABS failure can help diagnose and fix the problem quickly.

Several parts work together in the ABS system. If one part stops working, the whole system may fail. Here are some of the most common reasons for ABS failure.

Faulty Wheel Speed Sensors

Wheel speed sensors track the speed of each wheel. They send this data to the ABS control module. Dirt, damage, or wear can cause these sensors to fail. Faulty sensors lead to incorrect wheel speed readings. This causes the ABS warning light to turn on and the system to stop working.

Damaged Abs Control Module

The ABS control module is the brain of the system. It processes signals from the wheel speed sensors. If this module gets damaged, it may not work properly. Common causes include water damage and electrical faults. A damaged control module often triggers an ABS error message.

Wiring And Connector Issues

Wiring connects the ABS components. Connectors link wires to sensors and the control module. Over time, wires can break or corrode. Connectors may become loose or dirty. These issues cause poor communication between parts. This leads to ABS failure or warning lights.

Hydraulic Pump Malfunctions

The hydraulic pump controls brake pressure during ABS activation. A malfunctioning pump cannot adjust the pressure correctly. This affects the braking performance and safety. Common problems include motor failure or leaks in the pump system. Pump issues often cause the ABS light to stay on.

Diagnosing Abs Problems

Diagnosing ABS problems in a Freightliner truck is a key step to fix the issue quickly. The ABS system helps keep the truck safe by stopping the wheels from locking during braking. When the ABS warning light appears, it means the system needs attention. Understanding how to diagnose these problems can save time and money.

This process involves checking the system with tools, visually inspecting parts, and reading error codes. Each step gives clues about what might be wrong. Proper diagnosis ensures the repair is accurate and prevents further damage.

Using Diagnostic Tools

Diagnostic tools connect to the truck’s computer system. They scan the ABS system for faults. These tools show detailed information about sensor failures or electrical problems. Mechanics use these tools to pinpoint the exact issue. This method is faster and more reliable than guessing.

Visual Inspection Steps

Start by checking the ABS sensors on each wheel. Look for dirt, damage, or loose wires. Inspect the wiring harness for cuts or wear. Check the ABS control module for corrosion or water damage. Sometimes, simple cleaning or tightening a connection fixes the problem.

Reading Abs Error Codes

Error codes stored in the truck’s computer reveal specific ABS faults. Use a scanner to read these codes. Each code corresponds to a particular problem, like sensor failure or circuit faults. Reading the codes guides the mechanic to the exact area needing repair. This step saves time and avoids unnecessary replacements.

Quick Fixes For Abs Issues

ABS issues in a Freightliner can disrupt your vehicle’s safety and performance. Quick fixes often solve common problems without costly repairs. Understanding these fixes helps you keep your truck running smoothly. This section covers simple steps to try before seeking professional help.

Resetting The Abs System

Resetting the ABS system can clear minor errors. Start by turning off the engine and disconnecting the battery. Wait for 15 minutes to let the system reset. Reconnect the battery and start the truck. Check if the ABS warning light turns off. This method can fix small glitches in the system.

Cleaning Wheel Speed Sensors

Wheel speed sensors detect wheel rotation and send signals to the ABS. Dirt or debris can block these sensors. Locate the sensors near each wheel hub. Use a soft brush or cloth to clean around the sensor. Remove any buildup carefully. Clean sensors improve signal accuracy and ABS function.

Repairing Wiring Connections

Damaged wiring can cause ABS faults. Inspect wires near sensors and the ABS control module. Look for cuts, corrosion, or loose connections. Secure any loose wires and clean corroded areas. Replace damaged wires if needed. Proper wiring ensures the ABS receives the correct signals.

Replacing Faulty Components

Some ABS parts wear out over time. Common faulty components include sensors, control modules, and pumps. Test parts with a diagnostic tool to find faults. Replace any damaged parts with new ones. Using quality replacements restores ABS reliability and safety.

When To Seek Professional Service

Knowing when to seek professional service for your Freightliner’s ABS system is crucial. ABS problems can affect your truck’s safety and performance. Some issues need simple fixes. Others require expert care. Understanding the signs and making the right choice saves time and money.

Signs Beyond Quick Fixes

ABS warning lights that stay on signal serious problems. Strange noises during braking also need attention. If your brakes feel weak or respond late, do not ignore it. Repeated ABS failure after resets means deeper issues. These signs show your truck needs professional service, not DIY fixes.

Choosing A Qualified Technician

Pick a technician with Freightliner experience. Proper training ensures accurate diagnosis and repair. Certified technicians use the right tools and parts. Avoid uncertified shops to prevent further damage. Trust experts who understand Freightliner ABS systems well.

Service Costs And Expectations

ABS repair costs vary by issue severity. Expect higher costs for sensor replacements or module repairs. Ask for detailed estimates before work starts. Quality service may cost more but saves future expenses. Professional repair helps keep your Freightliner safe and reliable.

Preventive Maintenance Tips

Preventive maintenance helps keep your Freightliner’s ABS system working well. Regular care stops problems before they start. It also saves money on repairs and keeps your truck safe on the road. Follow these simple tips to avoid the “ABS Not Working Service Required” warning.

Regular Abs System Checks

Check the ABS system often for any signs of trouble. Use a scanner tool to read error codes. Look for warning lights on your dashboard. Early detection helps fix small issues fast. Schedule professional inspections to ensure the system works correctly.

Protecting Sensors And Wiring

Keep ABS sensors clean and free from dirt. Inspect wiring for cracks or damage regularly. Avoid harsh chemicals that can harm sensor parts. Secure wires to prevent them from rubbing or breaking. Healthy sensors mean accurate ABS function.

Maintaining Brake Fluid Levels

Check brake fluid levels regularly. Low fluid can cause ABS failure. Use the correct brake fluid type for your Freightliner. Replace old brake fluid as recommended by the manufacturer. Proper fluid levels keep brakes and ABS working smoothly.

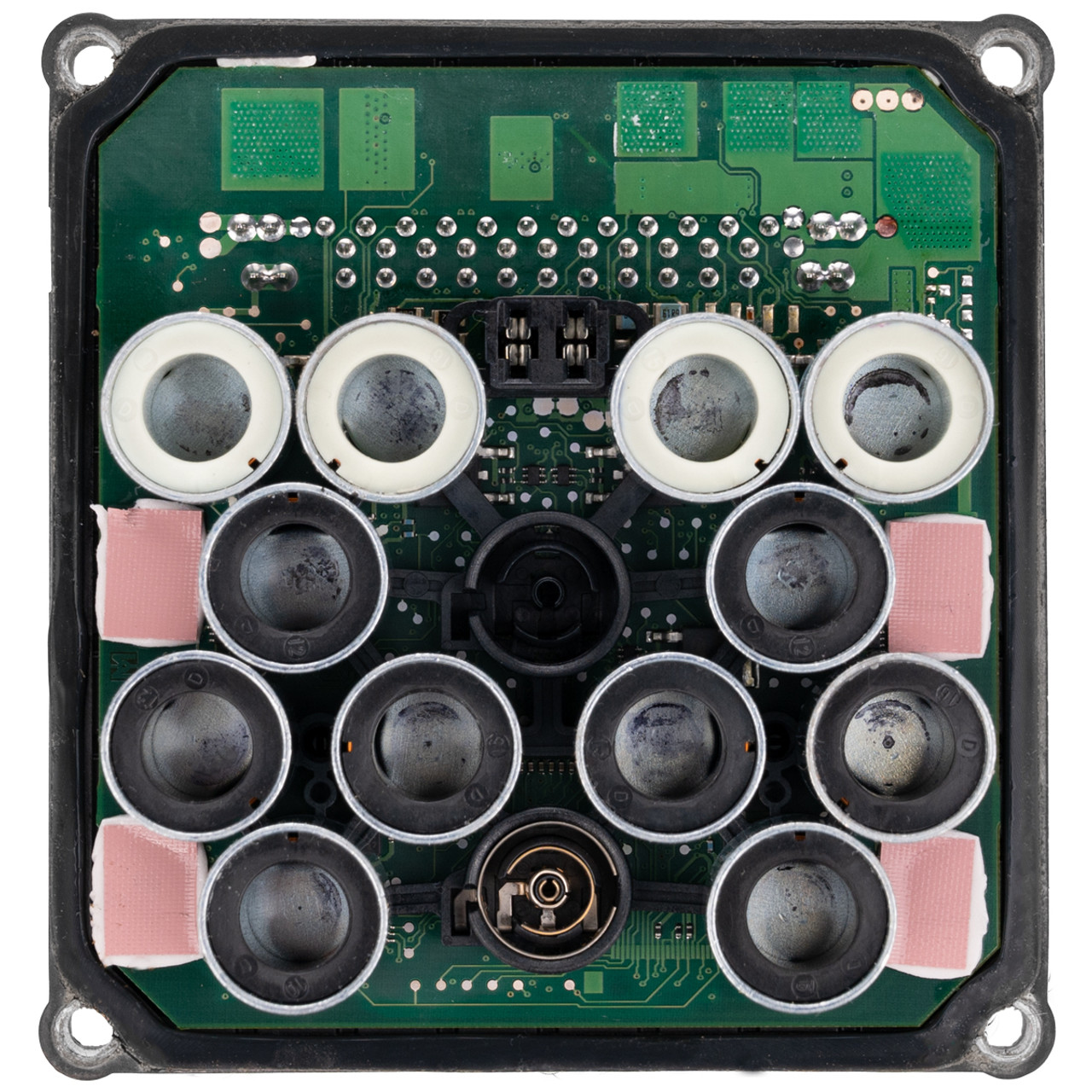

Credit: circuitboardmedics.com

Credit: www.youtube.com

Frequently Asked Questions

Why Does The Abs Light Stay On In Freightliner Trucks?

The ABS light stays on due to sensor faults, wiring issues, or ABS module failure.

What Does “service Required” Mean For Freightliner Abs?

“Service Required” signals a problem in the ABS system needing professional inspection.

How To Reset Abs After Repair On Freightliner Trucks?

Reset the ABS by disconnecting the battery or using a diagnostic scanner tool.

Can I Drive A Freightliner With Abs Not Working?

Driving without ABS is risky as it reduces braking control and safety.

What Causes Abs Failure In Freightliner Trucks Most Often?

Common causes include damaged wheel speed sensors, low brake fluid, or electrical problems.

Conclusion

ABS not working in your Freightliner signals a serious issue. Fixing it quickly keeps you safe on the road. Regular checks help spot problems early. Trust only skilled mechanics for the repair. Ignoring ABS faults can lead to costly damage.

Stay alert, maintain your truck, and drive with confidence. Your Freightliner deserves proper care to perform well every day. Safety and reliability go hand in hand. Don’t wait until trouble grows bigger. Act now to protect your vehicle and yourself.