Are you noticing your GM vehicle acting strangely or losing power unexpectedly? If your car has cylinder deactivation technology, these issues might be linked to GM cylinder deactivation problems.

This system is designed to save fuel by shutting off some cylinders when full power isn’t needed. But when it malfunctions, it can cause rough idling, reduced performance, or even warning lights on your dashboard. Understanding what’s going wrong and how to fix it can save you time, money, and frustration.

Keep reading to discover the common signs, causes, and solutions for GM cylinder deactivation problems—so you can get your ride running smoothly again.

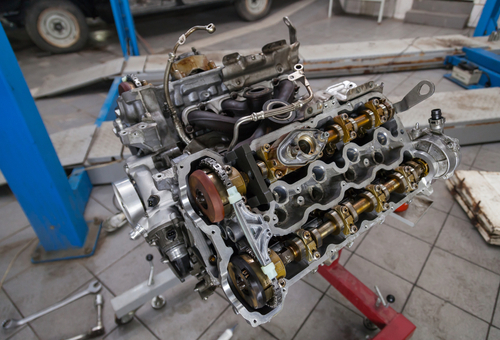

Credit: www.youtube.com

Common Causes Of Gm Cylinder Deactivation Issues

GM cylinder deactivation is a technology that saves fuel by turning off some engine cylinders. Problems with this system reduce fuel efficiency and cause engine trouble. Understanding common causes helps diagnose and fix issues faster.

Several factors can stop the cylinder deactivation system from working properly. These range from mechanical faults to electrical problems. Identifying the root cause is key to restoring smooth engine performance.

Faulty Solenoids And Actuators

Solenoids and actuators control the cylinder deactivation process. When these parts fail, cylinders may not deactivate correctly. Dirt, wear, or electrical failure often causes solenoid issues. Replacing faulty solenoids usually solves the problem.

Oil Pressure Problems

The system needs proper oil pressure to function. Low oil pressure can prevent cylinder deactivation. Oil leaks, dirty oil, or a failing oil pump affect pressure. Regular oil changes and checks help maintain correct pressure.

Electrical And Wiring Faults

Wiring connects sensors and control units. Broken or damaged wires disrupt signals. Corrosion or loose connections also cause faults. Inspecting and repairing wiring restores system communication.

Engine Control Module Errors

The engine control module (ECM) manages cylinder deactivation. Software bugs or hardware faults create errors. These errors trigger warning lights and reduce system function. Updating or replacing the ECM can fix these issues.

Wear And Tear On Engine Components

Over time, engine parts wear out and affect deactivation. Worn lifters, valves, or pistons cause malfunction. Regular maintenance and part replacement prevent long-term damage.

Credit: trade.mechanic.com.au

Symptoms Of Cylinder Deactivation Failures

Cylinder deactivation helps save fuel by shutting off some engine cylinders. When this system fails, the engine may show clear signs. Noticing these symptoms early can prevent bigger problems. Here are the common signs of cylinder deactivation failures in GM vehicles.

Engine Misfires And Rough Idle

The engine may misfire or run unevenly. You might feel shaking or roughness when the car is idle. This happens because some cylinders do not work properly. Misfires can harm engine parts over time.

Reduced Fuel Efficiency

Fuel consumption may increase unexpectedly. The system cannot shut off cylinders to save fuel. This leads to more gas being used than usual. Drivers may notice they need to refuel more often.

Check Engine Light Activation

The check engine light on the dashboard might turn on. This alerts the driver to a problem in the engine system. A diagnostic scan can show if cylinder deactivation is the cause. Ignoring this light can lead to serious damage.

Unusual Engine Noises

Strange sounds may come from the engine. Clicking, knocking, or tapping noises are common. These noises occur when cylinders fail to deactivate properly. Such sounds should not be ignored as they indicate mechanical issues.

Performance Loss

The vehicle may feel less powerful or slow to accelerate. This happens because the engine does not run smoothly. Cylinder deactivation problems can reduce overall engine performance. This affects driving comfort and safety.

Diagnostic Steps For Identifying Problems

Diagnosing problems with GM cylinder deactivation requires careful steps. Each step helps narrow down the cause. This process saves time and avoids unnecessary repairs. Following a clear method ensures accurate results and efficient fixes.

Reading Trouble Codes

Start by connecting an OBD-II scanner to the vehicle. Read any stored trouble codes. These codes point to specific faults in the cylinder deactivation system. Note down all codes for reference. Clear the codes after reading to check if they return.

Visual Inspection Of Components

Inspect all related parts for visible damage. Look for broken wires, loose connectors, or oil leaks. Check the actuator and solenoid for signs of wear. Dirt or corrosion can affect the system’s function. Clean or replace parts as needed.

Testing Solenoid Operation

Use a multimeter to test the solenoid’s electrical resistance. Compare readings to the manufacturer’s specifications. Activate the solenoid and listen for clicking sounds. No sound or incorrect resistance indicates a faulty solenoid. Replace faulty solenoids promptly.

Checking Oil Levels And Quality

Low or dirty oil can cause cylinder deactivation problems. Check the engine oil level using the dipstick. Inspect oil color and texture for contamination. Change oil if it looks dark or gritty. Use the recommended oil type for your GM engine.

Using Scan Tools For Live Data

Connect a scan tool to view live engine data. Monitor parameters like oil pressure and solenoid status. Look for irregular patterns or slow response times. Live data helps identify intermittent issues. Use this information to guide further repairs.

Effective Repair Solutions

Dealing with GM cylinder deactivation problems requires clear and effective repair solutions. Proper fixes help restore engine performance and improve fuel efficiency. These repairs target common issues that cause cylinder deactivation to fail or act irregularly.

Understanding these solutions can save time and reduce repair costs. Each fix addresses specific parts of the cylinder deactivation system. Let’s explore the key repair methods that ensure smooth engine operation.

Replacing Faulty Solenoids

Solenoids control the cylinder deactivation process. Faulty solenoids often cause misfires or rough engine running. Replacing damaged solenoids restores proper valve control. This repair helps the engine deactivate cylinders correctly. Using high-quality solenoids ensures lasting results and better engine response.

Fixing Wiring And Connector Issues

Wiring problems can disrupt the cylinder deactivation system. Loose or corroded connectors cause signal loss or errors. Inspecting and repairing wiring restores communication between parts. Cleaning connectors and securing wires prevents future electrical faults. Proper wiring fixes improve system reliability and engine smoothness.

Updating Or Reprogramming The Ecm

The Engine Control Module (ECM) manages cylinder deactivation. Sometimes, software glitches cause improper cylinder control. Updating or reprogramming the ECM clears these issues. This process adjusts the system to factory settings or newer versions. It helps the engine run efficiently and reduces error codes.

Performing Engine Tune-ups

Regular tune-ups support cylinder deactivation function. Replacing spark plugs and filters improves engine firing. Checking fuel injectors and sensors enhances overall performance. Tune-ups keep the engine clean and responsive. This prevents cylinder deactivation problems from developing.

Regular Oil Changes And Maintenance

Clean oil is vital for cylinder deactivation parts. Dirty oil causes sludge and clogs valves or solenoids. Changing oil at recommended intervals protects the system. Proper maintenance extends engine life and ensures smooth cylinder operation. It keeps the whole engine running at its best.

Preventive Tips For Cylinder Deactivation

Preventing cylinder deactivation problems in GM engines starts with simple care steps. These tips help keep the system working smoothly. They reduce wear and avoid costly repairs.

Using High-quality Engine Oil

Choose engine oil that meets GM’s specifications. High-quality oil protects engine parts and reduces friction. It helps the cylinder deactivation system work properly. Clean oil keeps valves and lifters from sticking.

Maintaining Proper Oil Change Intervals

Change the oil at the recommended times. Old oil loses its ability to protect the engine. Regular oil changes keep the oil clean and effective. This prevents build-up that can block cylinder deactivation parts.

Monitoring Engine Performance Regularly

Check your engine for unusual sounds or rough running. Early signs of problems can save money and time. Use an OBD-II scanner to find error codes. Fix issues before they damage the cylinder deactivation system.

Avoiding Prolonged Idling

Do not let the engine idle for too long. Prolonged idling can cause oil sludge and wear. This affects cylinder deactivation valves and sensors. Turn off the engine when waiting to protect the system.

Scheduling Routine Engine Inspections

Have a mechanic inspect your engine regularly. They can spot wear or damage early. Routine checks ensure the cylinder deactivation system stays in good shape. Replace worn parts before they cause failure.

Credit: www.enginelabs.com

Frequently Asked Questions

What Causes Gm Cylinder Deactivation Problems?

Cylinder deactivation issues often stem from faulty lifters, oil problems, or software glitches.

How To Detect Cylinder Deactivation Failure In Gm Engines?

Look for rough idling, engine misfires, or the check engine light turning on.

Can Bad Oil Affect Gm Cylinder Deactivation?

Yes, dirty or low oil can cause cylinder deactivation to malfunction.

Is Cylinder Deactivation Repair Costly For Gm Vehicles?

Repair costs vary but usually involve parts and labor, sometimes reaching several hundred dollars.

How Often Should Gm Cylinder Deactivation System Be Serviced?

Regular oil changes and engine checks every 5,000 to 7,500 miles help maintain the system.

Conclusion

GM cylinder deactivation problems can affect your engine’s performance. These issues may cause rough idling, reduced fuel efficiency, or warning lights. Regular maintenance helps spot problems early. Pay attention to unusual sounds or engine behavior. Fixing issues quickly saves money and avoids bigger repairs.

Understanding the basics keeps you informed and prepared. Stay alert to signs your car shows. Taking care of your vehicle ensures it runs smoothly. Simple checks can prevent major troubles later on. Keep your GM running at its best.