Is your Halo Bolt air compressor suddenly not working when you need it most? It’s frustrating, especially when you rely on it for quick and easy tasks.

You might be wondering what went wrong and how to fix it fast. You’ll discover simple steps to troubleshoot your compressor and get it back up and running without stress. Keep reading—you’ll save time, avoid costly repairs, and have your Halo Bolt working like new again.

Common Causes

The Halo Bolt air compressor may stop working due to several common issues. Knowing these causes helps you find the problem fast. It also saves time and money on repairs. Below are the main reasons your compressor might fail.

Power Supply Issues

Power problems often cause the compressor to stop working. Check the plug and outlet for damage or loose connections. A tripped circuit breaker can cut off power. Make sure the power switch is on. Faulty wiring inside the unit may also cause power loss.

Air Leaks

Leaks in hoses or fittings reduce air pressure. This makes the compressor work harder or stop. Listen for hissing sounds near connections. Use soapy water to find bubbles from leaks. Tighten or replace damaged parts to fix leaks.

Faulty Pressure Switch

The pressure switch controls the compressor’s start and stop. A broken switch can prevent operation. It may fail to sense pressure correctly. Test the switch with a multimeter for continuity. Replace the switch if it does not work.

Clogged Air Filters

Dirty filters block airflow and strain the compressor. This can cause overheating or shut down. Remove and clean filters regularly. Replace filters if they are too dirty or damaged. Clean filters keep air flowing smoothly.

Credit: www.youtube.com

Basic Troubleshooting Steps

Basic troubleshooting helps find simple problems fast. It saves time and avoids extra costs. Follow these steps to check your Halo Bolt air compressor.

Check Power Connections

Make sure the air compressor is plugged in securely. Check the power cord for damage. Confirm the outlet works by testing with another device. Look for tripped circuit breakers or blown fuses.

Inspect For Air Leaks

Listen for hissing sounds near the hose and fittings. Use soapy water on joints to spot bubbles. Tighten loose connections carefully. Replace worn or cracked hoses to stop leaks.

Clean Or Replace Filters

Dirty filters block airflow and reduce performance. Remove the air filter and inspect it. Clean it with compressed air or wash if washable. Replace the filter if it is torn or very dirty.

Reset The Pressure Switch

The pressure switch controls the compressor’s start and stop. Turn off the compressor and unplug it. Wait a few minutes to let it reset. Plug it back in and turn it on to test.

Quick Fixes For Electrical Problems

Electrical problems often cause the Halo Bolt air compressor to stop working. These issues can be simple to fix with basic checks. Quick fixes can save time and money before calling a professional. Follow these steps to find and solve common electrical problems.

Test The Power Outlet

Start by testing the power outlet. Use another device to check if the outlet works. A dead outlet means no power for the compressor. Try plugging the compressor into a different outlet. This helps confirm the problem is with the original outlet.

Replace Blown Fuses

Blown fuses stop electrical flow to the compressor. Locate the fuse box or fuse holder on the unit. Remove the fuse and check for any breaks or dark marks. Replace a blown fuse with one of the same type and rating. A new fuse can restore power quickly.

Examine Wiring And Connections

Loose or damaged wires cause power interruptions. Inspect the wiring for cuts, frays, or corrosion. Check all connections to ensure they are tight and secure. Fix any damaged wires or connectors carefully. Good wiring is essential for safe and steady power.

Addressing Mechanical Issues

Mechanical problems often cause the Halo Bolt air compressor to stop working. These issues can block normal operation and reduce the tool’s life. Fixing mechanical faults helps keep the compressor running smoothly and safely. Checking for loose parts, adding oil, and changing worn seals can solve many common problems.

Tighten Loose Components

Loose parts can cause noise, vibration, and poor air pressure. Use a wrench to check bolts and screws. Tighten any that move or feel weak. This simple step prevents parts from falling off or breaking. Regularly tightening parts keeps the compressor stable and effective.

Lubricate Moving Parts

Moving parts need oil to work well. Lack of lubrication causes friction and wear. Apply oil to pistons, bearings, and other moving pieces. Use the type of oil recommended by the manufacturer. Proper lubrication reduces heat and noise. It also helps the compressor last longer.

Replace Worn Seals

Seals keep air and oil inside the compressor. Worn or broken seals cause leaks and lower pressure. Inspect seals for cracks or damage. Replace any seals that look weak or old. New seals restore full power and stop leaks. This step is key to fixing performance issues.

When To Seek Professional Help

Knowing when to seek professional help for your Halo Bolt air compressor saves time and money. Some problems need expert skills and tools. Trying to fix complex issues alone might cause more damage. Recognize signs that require a technician’s attention.

Persistent Performance Problems

If your air compressor struggles to reach or hold pressure, it signals a problem. Frequent stops or slow operation also indicate trouble. Simple fixes might not solve ongoing issues. Persistent problems affect your work quality and safety. Professionals can diagnose hidden faults quickly and fix them properly.

Complex Internal Repairs

Internal parts like valves, pistons, and motors need special knowledge to repair. Opening the compressor without experience risks breaking parts or voiding warranties. Some repairs require precise tools and replacement parts. A professional can handle these safely and restore full function. Avoid guesswork with internal repairs.

Warranty Considerations

Your Halo Bolt air compressor may have a warranty covering repairs. Attempting DIY fixes can void this warranty. Professionals understand warranty terms and follow proper repair steps. Using authorized service keeps your warranty valid. Protect your investment by choosing certified technicians for repairs.

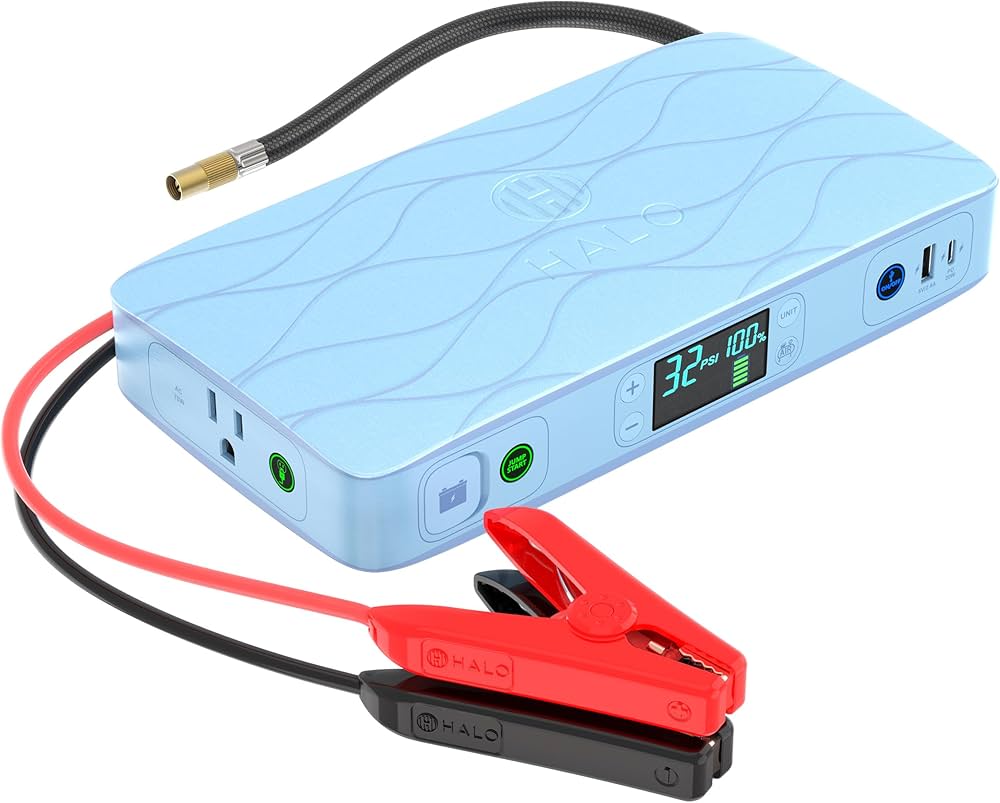

Credit: www.amazon.com

Maintenance Tips To Prevent Future Issues

Keeping your Halo Bolt air compressor in good shape saves time and money. Regular care stops many common problems before they start. Small actions can keep your machine running smoothly and last longer.

Regular Cleaning Schedule

Dust and dirt can block the air filter and reduce power. Clean the compressor’s exterior weekly. Use a soft cloth to wipe off dust. Check and clean the air filter every month. A clean filter helps the compressor breathe better.

Proper Storage Practices

Store the compressor in a dry, cool place. Avoid damp or dusty areas that can cause rust. Keep the machine covered to stop dust buildup. Store it upright to protect internal parts. Proper storage prevents damage and keeps it ready to use.

Routine Inspection Checklist

Check all hoses and fittings for leaks every week. Tighten any loose connections to avoid air loss. Look at the oil level and change it as needed. Test the pressure gauge for accuracy. Regular checks help spot problems early and keep the compressor safe.

Credit: www.ebay.com

Frequently Asked Questions

Why Is My Halo Bolt Air Compressor Not Turning On?

Check the power source and ensure the plug is firmly connected. Also, inspect the fuse or circuit breaker.

How To Fix A Halo Bolt Air Compressor That Won’t Build Pressure?

Look for air leaks and tighten fittings. Clean or replace the air filter if dirty.

What Causes Halo Bolt Compressor Motor To Overheat?

Overuse, poor ventilation, or low oil levels can cause overheating. Let it cool and check oil regularly.

Why Does The Halo Bolt Compressor Keep Shutting Off?

This may be due to thermal overload or a faulty pressure switch. Inspect and reset if needed.

How Do I Maintain My Halo Bolt Air Compressor For Better Performance?

Regularly clean filters, check oil, drain tank moisture, and inspect hoses for damage or leaks.

Conclusion

Troubles with your Halo Bolt air compressor can feel frustrating. Simple checks often fix common problems quickly. Make sure the power supply is steady and cables connect well. Clean or replace filters to keep air flowing right. Regular care helps the compressor work longer and better.

Don’t ignore strange noises or leaks; they need attention. Small fixes save time and money. Stay patient and follow easy steps to get your compressor running again. Your tools depend on good air pressure to do the job well. Keep it ready, and work stays smooth.