Submersible well pumps are essential for water systems. They ensure a steady water supply.

But like any equipment, they can face problems. Understanding submersible well pump issues is crucial for maintaining your water system. Whether it’s a drop in water pressure or strange noises, these problems can disrupt daily life. Knowing how to troubleshoot can save time and money.

This guide will help you identify common issues and offer solutions. From diagnosing electrical problems to fixing mechanical faults, we’ll cover it all. With the right knowledge, you can keep your well pump running smoothly. Stay tuned to learn how to tackle these challenges effectively.

Credit: apkpumps.com

Common Issues

Submersible well pumps are essential for many households. They provide a steady water supply. However, like all mechanical devices, they can face issues. Understanding common problems can help you troubleshoot and maintain your pump effectively.

Pump Not Running

If your pump is not running, check the power supply first. Ensure the pump is plugged in and the circuit breaker is not tripped. Inspect the control box for any signs of damage. If the pump still doesn’t run, the motor might be at fault. A professional should inspect it for further diagnosis.

Low Water Pressure

Low water pressure can be frustrating. It often indicates a problem with the pump. Check for any leaks in the pipes. Clogged filters or screens can also reduce pressure. Clean or replace them as needed. If the issue persists, the pump might be worn out. A professional inspection can determine if a replacement is necessary.

Electrical Problems

Electrical problems are common issues for submersible well pumps. These problems often disrupt the pump’s operation. They can cause significant inconvenience. Understanding these issues can help in troubleshooting and solving them effectively.

Blown Fuses

Blown fuses are a frequent electrical problem. They occur due to power surges or short circuits. Check the fuse box for any blown fuses. Replace any blown fuse with a new one of the same rating.

If the fuse blows again, there may be a deeper issue. It could be a short circuit or a faulty pump motor. In such cases, consult a professional.

Tripped Circuit Breakers

Tripped circuit breakers are another common issue. They usually trip due to overload or a short circuit. First, locate the circuit breaker panel. Inspect for any tripped breakers. Reset the breaker by flipping it off and then back on.

If the breaker trips again, it indicates a problem. It might be an electrical overload or a pump defect. Seek expert help to diagnose the issue.

Mechanical Failures

Mechanical failures can cause significant issues with submersible well pumps. These problems can reduce efficiency or halt the pump’s operations. Identifying and addressing mechanical failures is crucial for maintaining a reliable water supply.

Worn Out Impellers

Impellers play a key role in the pump’s operation. They move water from the well to the surface. Over time, impellers can wear out. This wear reduces the pump’s efficiency. The pump may struggle to move water as effectively as before. Regular inspection of the impellers helps prevent this issue.

Damaged Seals

Seals keep water out of the pump’s motor. Damaged seals can allow water to seep in. This can cause the motor to short-circuit or fail. Inspecting seals for damage is essential. Replacing damaged seals promptly prevents more severe problems. Ensuring seals are intact keeps your pump running smoothly.

Water Quality Concerns

Water quality is crucial for the performance of submersible well pumps. Poor water quality can lead to various issues. These problems can affect the pump’s efficiency and longevity. Two common issues are sediment buildup and corrosion. Let’s explore these in detail.

Sediment Buildup

Sediment in your well water can clog your submersible well pump. It can reduce the water flow. The pump works harder to move water. This strain can shorten the pump’s life. To fix this, install a sediment filter. Regularly clean and maintain the filter. This will keep sediment from reaching your pump.

Corrosion

Corrosion can damage your submersible well pump. It often occurs due to high mineral content in water. Corrosion weakens the pump parts. This can lead to leaks and pump failure. Use corrosion-resistant materials for your pump. Regularly check for signs of rust or wear. Addressing corrosion early can save you from costly repairs.

Pump Maintenance

Regular maintenance of your submersible well pump ensures its longevity and efficiency. Neglecting maintenance can lead to frequent breakdowns and costly repairs. This section focuses on key maintenance tasks for your pump.

Regular Inspections

Conduct regular inspections to detect issues early. Check for unusual noises, vibrations, or leaks. Inspect the electrical connections to ensure they are secure. Regularly monitor the water flow and pressure. These checks can help identify problems before they become serious.

Cleaning Procedures

Cleaning your submersible well pump is essential for its optimal performance. Start by turning off the power supply. Remove the pump from the well and clean the exterior. Use a soft brush to remove dirt and debris. For the interior, flush the pump with clean water. This helps remove any sediment build-up. Regular cleaning keeps the pump functioning smoothly.

Credit: inspectapedia.com

Tools & Equipment

Having the right tools and equipment is essential for troubleshooting submersible well pumps. It makes the job easier and ensures safety. This section covers the essential tools and safety gear needed for the task.

Essential Tools

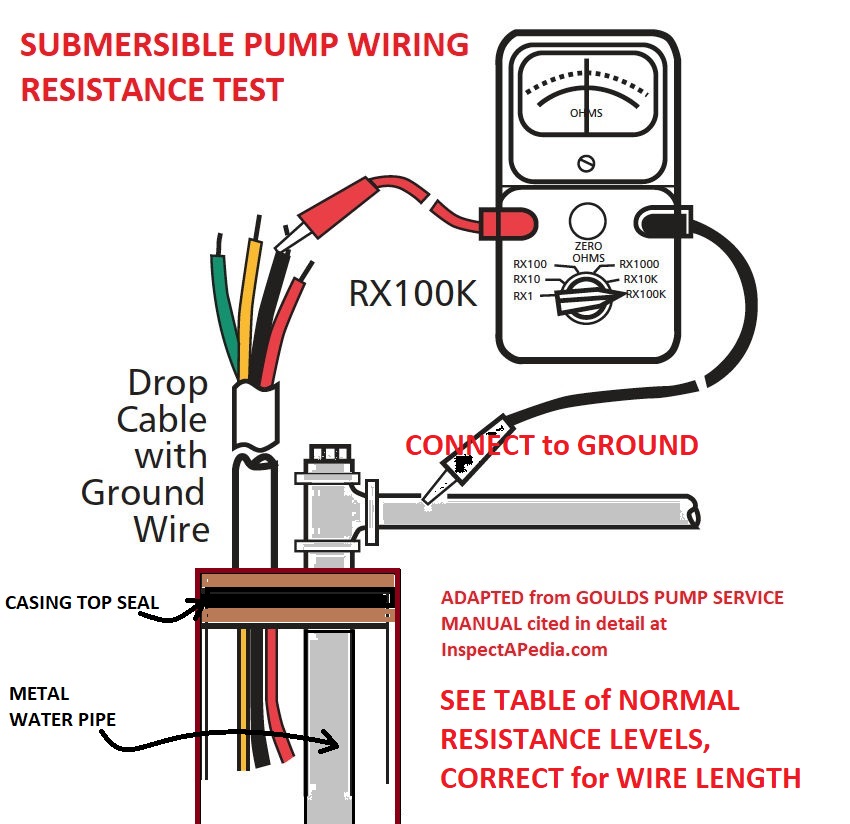

First, you need a multimeter. It helps check electrical connections. A pipe wrench is necessary to grip and turn pipes. You also need a set of screwdrivers. Choose both flathead and Phillips. Don’t forget pliers for gripping and cutting wires. An ammeter is useful to measure current flow. A flashlight is essential for seeing in dark well areas.

Having a voltage tester is crucial. It ensures power is off before working on the pump. Pipe cutters help in cutting through pipes cleanly. A pressure gauge checks the water pressure. A submersible pump puller makes removing the pump easier. Collecting these tools ensures you are prepared.

Safety Gear

Always wear protective gloves. They protect your hands from cuts and chemicals. Safety goggles shield your eyes from debris. Use ear protection in noisy environments. Non-slip boots provide good footing in wet areas.

Ensure you have a hard hat. It protects your head from falling objects. An insulated mat is vital when working with electricity. A dust mask prevents inhalation of particles. Wearing the right gear keeps you safe and reduces risk.

Professional Help

Submersible well pumps can sometimes have issues that need expert attention. While some problems can be fixed with basic knowledge, others require a professional touch. Seeking professional help ensures the pump’s longevity and efficiency. Below are two key considerations for getting expert assistance.

When To Call A Pro

Knowing when to call a professional can save time and money. Here are some situations where you should reach out for expert help:

- No Water Flow: If the pump is running but no water is coming out, a professional should inspect it.

- Strange Noises: Unusual sounds may indicate mechanical issues that require a trained eye.

- Frequent Cycling: If the pump turns on and off frequently, it might be an electrical problem.

- Low Water Pressure: Consistent low pressure could mean a problem with the pump or the well itself.

- High Energy Bills: An increase in energy costs may indicate that the pump is working harder than it should.

Choosing A Service

Picking the right service is crucial for effective repairs and maintenance. Here are steps to choose the best service:

- Research: Look for reviews and ratings of local services. Check their experience and expertise in submersible well pumps.

- Certifications: Ensure the service provider is certified and licensed. This guarantees they meet industry standards.

- Quotes: Get multiple quotes. Compare prices, but also consider the quality of service.

- Warranty: Choose services that offer a warranty on their work. This provides peace of mind and guarantees quality.

- References: Ask for references from previous customers. A good service will have a list of satisfied clients.

By following these steps, you can ensure your submersible well pump gets the best care possible. Proper maintenance and timely professional help can extend the life of your pump and keep your water supply reliable.

Credit: inspectapedia.com

Preventative Measures

Submersible well pumps are critical for accessing groundwater. Regular maintenance can prevent many common issues. Simple preventative measures can save time and money. Let’s explore some key steps.

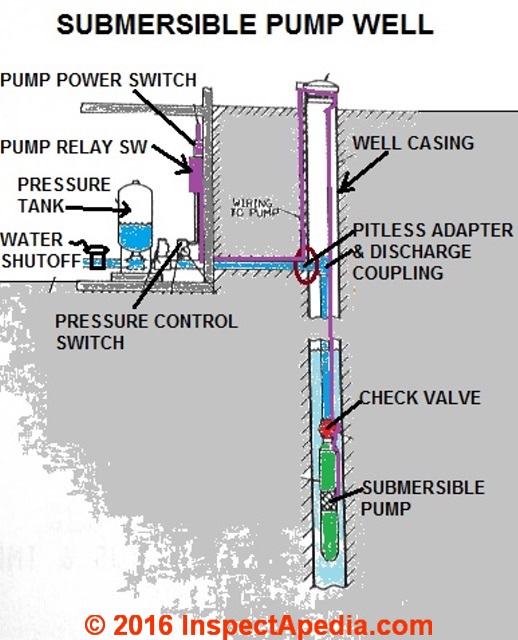

Proper Installation

Proper installation is crucial for the longevity of your submersible well pump. Ensure the pump is installed at the correct depth. This prevents it from running dry. Use a support rope to keep the pump stable. Make sure electrical connections are secure. Loose wires can cause short circuits. Follow the manufacturer’s guidelines. This reduces the risk of errors.

Here is a simple installation checklist:

- Check the well depth and water level.

- Use appropriate support ropes or cables.

- Ensure secure electrical connections.

- Follow manufacturer instructions.

Routine Checkups

Routine checkups are vital for maintaining your well pump. Conduct regular inspections to identify potential problems early. Inspect the pump for wear and tear. Check the electrical components for any signs of damage. Look for unusual noises during operation. This can indicate a problem.

Consider creating a maintenance schedule:

- Monthly: Inspect for wear and tear.

- Quarterly: Check electrical components.

- Annually: Conduct a thorough inspection by a professional.

A table can help keep track of routine checkups:

| Task | Frequency |

|---|---|

| Inspect for wear and tear | Monthly |

| Check electrical components | Quarterly |

| Professional inspection | Annually |

Frequently Asked Questions

Why Is My Submersible Well Pump Not Working?

A submersible well pump might fail due to electrical issues, clogged filters, or worn-out components.

How Do I Reset My Submersible Well Pump?

Locate the reset switch on the pump or control box. Press it to reset the pump.

What Causes A Submersible Pump To Lose Pressure?

Loss of pressure can be due to leaks, blockages, or a failing pressure switch.

How Often Should I Service My Submersible Well Pump?

Service your pump every 1-2 years to ensure it works properly and lasts longer.

Can A Submersible Well Pump Be Repaired?

Yes, many issues can be fixed. Consult a professional if you’re unsure about the problem.

Conclusion

Troubleshooting a submersible well pump can seem challenging. Follow these simple steps. Check for power issues first. Inspect the pump’s wiring and connections. Ensure the pressure switch is working. Clean or replace clogged filters. Listen for unusual noises. These can indicate mechanical problems.

Regular maintenance prevents many issues. Keep your pump in good condition. This ensures it works efficiently. Always consult a professional for major repairs. Your submersible well pump will last longer. And provide reliable water supply.